About Rubber Conveyor Belts

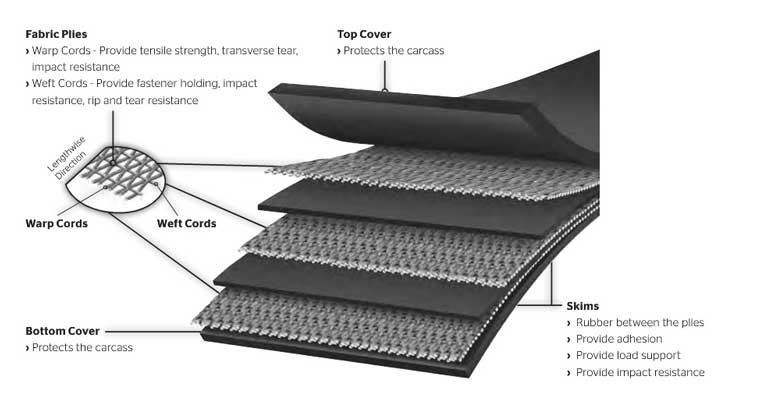

A rubber conveyor belt is a type of continuous moving belt that transports materials or packages from one place to another. In other words, this is a solid band made of tough, long-lasting substances, upon which different materials are conveyed. They are made from a variety of materials, ranging from rubber compounds and leather to urethane and PVC to wire mesh composed of assorted metals, like stainless steel and carbon steel. Rubber conveyor belts are very popular and widely used in various industries to transport and process materials from one point to another. They are widely used in conveyor systems. Multiple belting are used to transfer or shift power from one rotating shaft to another on conveyor systems. They are available for a wide range of applications and media transportation. Production, mining and shipping companies all make use of conveyor belts to manage materials more efficiently and reduce labor costs.

Our Conveyor belts are best used in Road Construction, Power Plats, Cements Industries, Steel Plants, Stone Crushers, Paper Industries, Sugar Mill etc.